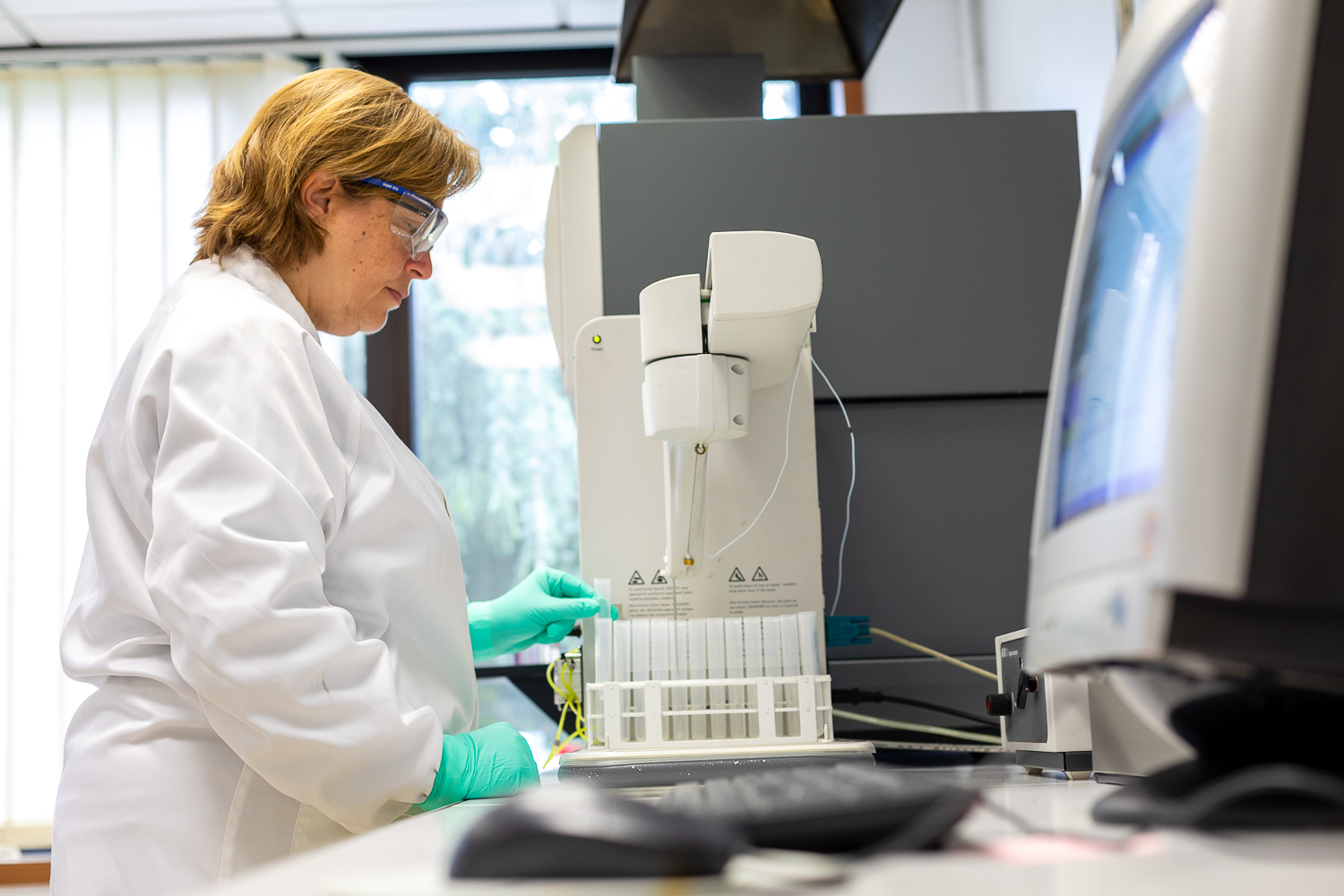

Thanks to its significant experience in the study of materials and finished products, SFC supports manufacturers in the analysis and expertise of their materials through adapted tests.

The analysis laboratory offers a wide range of equipment regularly renewed and checked.

In order to meet the needs of its customers, the laboratory is proactive in developing new testing methods.

The benefits

It is essential for manufacturers to develop and increase their knowledge on products and materials at all stages of marketing. SFC offers a wide range of services to perform on various products and materials:

Elementary composition analyzes

Quality controls

Pollutants or impurities research

Material expertise following a failure

Chemical analyzes following a failure

Deformulations of products

Training on the methods developed

Benchmarking studies

Validations of methods transferable to the client

Development of test methods

Method validations

Regulatory survey

The tests proposed by SFC teams are carried out with reference to French, European or international standards or regulations, or according to specifications defined with its customers.

The ways

Fluorescence X Spectrometer

ICP MS plasma emission spectrometer

UV Spectrophotometer

High temperature kiln

ICP OES Spectrometer

Carbon and sulfur infrared combustion & absorption analyser

PH meter

The quality approach

SFC has a number of labels, approvals and recognitions that testify its professionalism and its involvement in Research and Innovation. In particular, it has the agreement “Crédit impôt recherche” (CIR) Research Tax Credit, with a doubling of the tax base calculation.

SFC also possesses a quality management system that meets the requirements to the NF EN ISO 17025 standard.

SFC is thus Cofrac Essais, n°1-0062 accredited (scope available on www.cofrac.fr) according to the NF EN ISO 17025 standard.