SFC performs a large number of R&D and Innovation works in partnership with French and European companies and laboratories on multiple subjects. The contribution of SFC innovation in businesses, particularly SMEs-SMIs, is essential for the development of these markets.

SFC experts provide support to industrials in traditional sectors or new technologies, with tailor-made solutions to increase understanding and control of the behavior of materials, products and works and to develop technological innovation from the process diagnostic to the product or system validation.

The strengths of SFC

SFC offers partner companies support for setting up and preparing their projects, thus providing real skills and experience (project coordinator, administrative expertise, contacts with funding organizations, networks of experts and competence centers, etc.).

Integrating into its projects a collaborative dynamic, based on its own means of characterization, expertise and specialized services, SFC mobilizes all of its resources to launch and carry out study programs and Research & Innovation works. The various service offers of SFC are thus mobilized:

- Finished product testing

- platform

- Materials characterization

- laboratory

- Expertise service

- Environment department

- Technological Survey service

- Standardization Bureau

SFC has a strong experience in the management and coordination of programs for its own projects and in support of partner companies engaged in R&D programs or on public funding schemes.

A specific program coordination function dedicated to the supervision, monitoring and professionalization of these tasks has been created for this purpose to offer full support to partners.

The management of SFC Research and Innovation projects is thus ensured at several levels:

- Project management (respect of milestones, deadlines)

- Control of laboratory works orientation

- Management of resources allocated to projects

- Promotion and communication actions

- Respect of confidentiality

- Support until industrialization

Themes

The SFC’s Research themes are transversal and concern all industrial sectors and their applications. These themes are oriented both for professionals in the sectors concerned, who wish to see their products evolve, and for users who wish to compare product performance.

R&D axes of study

Products development

Environmental impacts,

Health & Safety

Processes

This area focuses on optimizing the functionality and performance of products, as well as their specific applications.

This axis concerns the reduction of impacts such as the recovery of industrial residues, the reduction of energy costs, the resources efficiency and the control of liquid and atmospheric effluents.

This axis relates to the optimization of processes and materials. This theme targets the different stages of the processes and their optimization in terms of energy and / or environment.

Examples of applications

Rheological optimization of mineral suspensions

Improvement of rheological properties to reduce manufacturing process costs

Development of ceramics mechanical resistance to mechanical stresses

New product for use in high temperature kilns.

Environmental impact study

Integration of the environment in the development of a project, and this from the upstream phases of reflections.

Bibliographic study on non-destructive testing methods and materials

The benefits

SFC’s means are based on manufacturing processes and products to proprose a whole series of associated characterizations. The possibility of reproducing on a laboratory scale all the manufacturing processes of the mineral industry allows SFC to be the privileged partner for the realization of studies on the following services:

Characterization of processes

- Primary crushing

- Dry or wet grinding (0.5 to 50 kg)

- Granulometry

- CEC with Methylene Blue

- Mixtures and dispersions (0.5 to 100 kg)

- Density measurement

- Viscosity measurement (Ford Cup and Gallenkamp)

- Rheological study

- Shaping:

- Vacuum extrusion (1 to 10 kg)

- Pressing (0.6 to 60 MPa)

- Casting

- Plasticity (Atterberg limits)

- Pressure filtration kinetics (from 0 to 20 bars)

- Drying

- Desorption curves and Bigot

- Drying shrinkage monitoring

- Glazing by:

- Spray

- Soaking

- Bar-coating

- Dynamics of fusion

- Fusing kinetics

- Firing (up to 1700 ° C)

- Atmosphere control (O2; CO)

- Pyroplastic deformation

Characterization of products

- Shrinkage

- Cohesion

- Color L * a * b *

- Porous texture

- Thermal expansion

- Moisture expansion

- Mechanical properties

- brightness

- Abrasion

- Roughness

- Glaze/body fitting

Documentary studies

- Technology and scientific intelligence

- Bibliographic research

SFC also offers tailor-made testing method development and validation services.

The tests carried out by SFC teams are carried out with reference to French, European or international standards or regulations, or according to specifications defined with its customers.

Ways

Crusher – Cylindrical delaminator

Preparation of feldspar or clay powders and plastic materials.

Delayer – Mixer – Granulator

Preparation of powders for liquid or dry way.

Capacity: from 0.5 to 50 kg.

LEARN MORE

Pressing

Dry mass shaping.

Uniaxial pressing.

Humidity: 5 to 6%.

Pressure: from 0.6 to 60 MPa.

Barcoating – Spraying with a spray gun – Glazing chamber

Glazing.

Density: from 1.6 to a high density (barcoating).

Rotap granulometer

Grain size measurement.

Grain size: greater than 40 µm.

RM200 rheometer

Rheology and plasticity (flow curve, fluid behavior, thyxotropy, etc.).

LEARN MORE

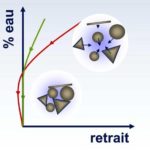

Bigot curve

Rheology and plasticity.

Measurement of drying shrinkage.

Enables you to understand the drying kinetics of interstitial waters and colloidal waters.

Inclined plan

Behavior during cooking.

Tilt: 45°.

Study of the fusibility and viscosity of a glaze.

CeramBase

Bibliographic database, with complete references and abstracts.

Quick access to more than 10,000 references from international publications.

Ball mill – Planetary mill

Preparation of powders dry or wet.

Different capacities: from 200 g to 30 kg of matter.

Grain size: from 2 to 5 mm -> D50: 40 µm

Extruder

Shaping of plastic pastes.

Screw extruder.

Humidity: 20%.

Capacity: 2 kg.

Vacuum extruder.

Casting

Shaping of the masses.

Casting in porous mold or under pressure.

Humidity: 40%.

Pressure: up to 20 bars.

Tubular electric kiln, high temperature, large capacity

Firing.

Different volumetric capacities.

LEARN MORE

Gallenkamp viscometer

Viscosity measurement.

Measurement of the angle read during the rotation of the mobile.

Atterberg’s limits

Rheology and plasticity.

Heating microscope

Behavior during heating.

Evolution of the glaze sample subjected to a firing cycle by means of a thermal camera.

LEARN MORE

Gradient firing

Behavior during heating.

Gradient between the two ends of the kiln: 300°C.

LEARN MORE

CeramVeille

The Documentation Service has a large specialized document collection base.

In addition to these resources, the R&D department can rely on additional testing resources ranging from the characterization of powders to product performance tests.

Partnerships

The proximity of SFC to industrials, networks of experts and specialized structures allows it to form a network of multiple partnerships within the framework of research programs combining the actors of basic and applied research and the industrial world. SFC is also represented in several associations and networks of experts.

Ministerial actors

State agencies

Approvals

SFC has a number of labels, approvals and recognitions that testify its professionalism and its involvement in Research and Innovation. In particular, it has the agreement “Crédit impôt recherche” (CIR) Research Tax Credit, with a doubling of the tax base calculation.

SFC’s added value

Analysis of the need and definition of the results.

Quality and reliability of the services provided.

Independence of the analysis laboratory, the experts and the test plateform.

Confidentiality of works.

Cofrac accreditation according to the NF EN ISO 17025 standard (scope available in the quality approach).

90 years of experience in ceramic materials and processes.